Havarieset

Data acquisition in the event of an accident

For the standard-compliant operation of washer-disinfectors, the recording of all process faults in each

individual batch is mandatory. If this cannot be ensured, the operator must switch to another independent test method or take his RUMED or parts of it out of operation.

A simple possibility of batch control is offered by the following product compilation, which should not

be missing in any RUMED.

As part of an average concept, the use of data loggers can ensure standard compliant monitoring and the RUMED can continue to operate. Depending on the size of the RUMED but of course also based on the risk assessment, one or more such sets should be available.

Your Benefits are:

• Normative reprocessing despite average through independent measuring system

• No network infrastructure required, as data acquisition and evaluation takes place on a single workstation computer

• Calibrated measuring system

• TÜV certified evaluation software

An accident set should contain the following:

|

Type |

Description |

|

|

EBI 12-TP237 |

For measuring the temperature and rinsing pressure in the WD. It can also be used in the steam sterilizer. |

|

|

SI 2150 |

Software and interface set, consisting of the TÜV certified Software Winlog.med and the Interface IF 150 |

|

|

AL 101 |

Silikone protection box |

|

|

TDS-3 |

For checking the water quality of the last rinsing water, measurement of conductivity |

|

|

PHX 800 |

For checking the water quality of the last rinsing water, measurement of the pH value |

|

|

AL 128 |

Storage and transport case |

|

|

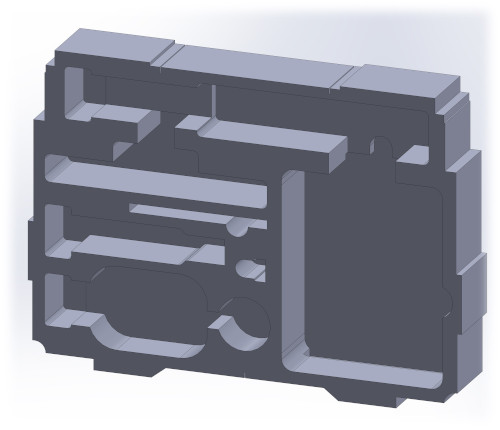

AL 1100 |

Foam insert |

|