Control de cadena de frío y de procesos

Cold chain management and process monitoring: for optimisation of product quality and loss minimisation

Management and process monitoring with regard to unbroken cold chains is generally the focus for foods which need to be kept cold. However, a cold chain management system is also needed under some circumstances for chemicals and other special products such as some high-tech devices, for example. Here, such a management system covers efficient supervision and process monitoring with regard to production and logistics temperatures. Temperature monitoring within the individual steps of the production, storage and the actual transport chain at the internal and inter-company level is very important here. But it is not only temperature monitoring which is important in the context of a cold chain, but also monitoring of the properties of the respective products, the technical equipment with regard to cooling, consideration of the laws and regulations and supply chain management as a process-oriented management approach: in their complex entirety, these are the factors, consideration of which is highly relevant.

Unbroken cold chains are not possible without professional measurement technology

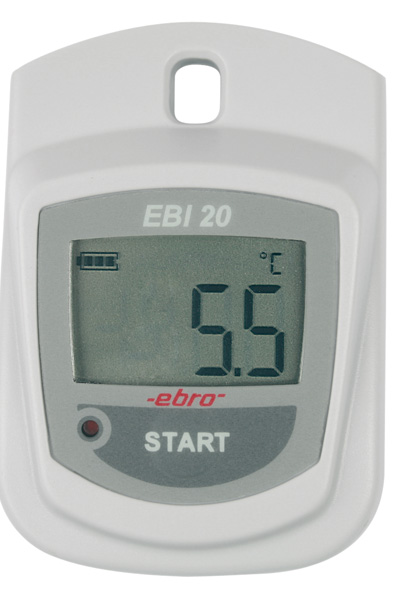

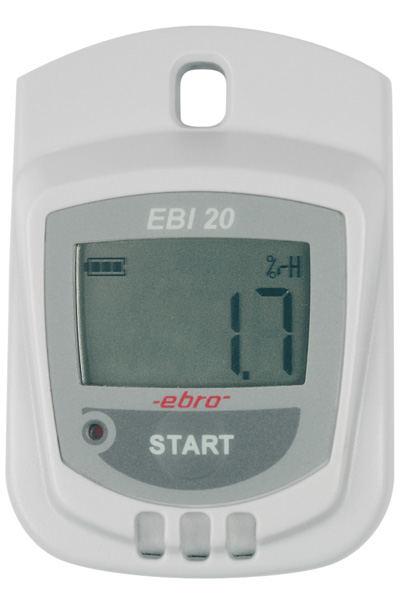

We present to you a broad product portfolio of diverse data loggers for cold chain and process monitoring. Our high-quality data loggers for temperature measurement as well as for measuring pressure and humidity in routine monitoring, and validation as well as process and cold chain monitoring give you access to unbroken cold chain management. Here, our range includes data loggers with radio technology for real-time monitoring, mini data loggers for confined spaces, multi-channel thermocouple data loggers, and complete data logger systems including the evaluation software. Our products are available with a wide range of configurations and sensor variants so that they fit your application perfectly.

Cold chain and process monitoring as a closed connection

Cold chains create a closed connection between production, the retail trade and consumers. The legislators therefore require that the minimum temperature within the entire cold chain for deep-frozen goods (for example food) is minus 18 degrees Celsius, whereby there may only be short-term fluctuations of a maximum of 3 degrees Celsius. Our data loggers provide meaningful support at the highest technical level so that you are always able to optimally meet all of the legal specifications with your cold chain and process monitoring in this context!